Why Foam?

Water has long been the universally accepted agent for suppressing fires. However, water is not the most effective agent in all cases. For example, water is typically not effective on an oil fire, and can be positively dangerous. The development of firefighting foams was a positive step toward solving the problem of extinguishing oil fires.

Class A Foam

Class A Foam is more effective than plain water on Class A type fires because plain water has inherent limitations in cooling and penetrating Class A fuels due to a naturally high surface tension. This high surface tension causes water to form into droplets, and consequently, the majority of the droplets roll off fuels, impeding water’s heat absorption potential.

Technically this foam is known as a 'synthetic detergent hydrocarbon surfactant' and, when mixed with water at the recommended ratios, is biodegradable. Because it is a hydrocarbon surfactant, it also has an affinity for carbons and causes the water (as foam solution) to penetrate deep into wood fuels.

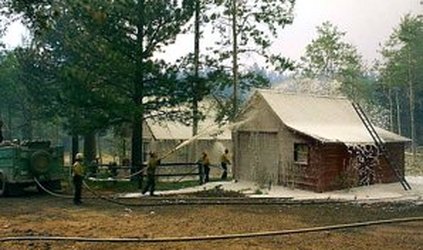

Class A Foam has wetting and penetrating characteristics to reduce the combustibility of Class A fuels and makes water 10 times more effective. It can be used with fresh, sea, or brackish water and can be stored for up to 25 years in its original container. Pretreating an area with foam can greatly reduce the chance that the area will burn. Class A foam will adhere to vertical surfaces, increasing the protection it can give to a structure. After the fire threat is passed, clean off any foamed areas with water if desired.

Foam can be aspirated (entrained with air) through a fog or air aspirating nozzle, or a Compressed Air Foam System (CAFS) such as the one we use here at Consumer Fire Products, Inc. Different quality of finished foam blankets can be formed using these foam generation devices. Forming a low expansion, quick draining finished foam bubble blanket will yield additional fire suppression proficiency upon direct attack by enabling the foam solution to adhere to horizontal and vertical fuels. It can literally stick to the sides of a building, tree, or other vertical structure. The foam solution will remain on the fuel, penetrating or evaporating, until it is all gone. The net effect of using Class A foam in this fashion is that the available water supply is efficiently used to cling to and cool the fuel. This maximizes water’s ability to suppress the fire, rather than being wasted by running off of it. Penetration of Class A Foam into fuels will increase their moisture content and prevent them from burning. In addition, the Class A Foam will act as a barrier between any fire and fuel.

Click HERE to see how how foam compares to gels and fire retardant

Class A Foam

Class A Foam is more effective than plain water on Class A type fires because plain water has inherent limitations in cooling and penetrating Class A fuels due to a naturally high surface tension. This high surface tension causes water to form into droplets, and consequently, the majority of the droplets roll off fuels, impeding water’s heat absorption potential.

Technically this foam is known as a 'synthetic detergent hydrocarbon surfactant' and, when mixed with water at the recommended ratios, is biodegradable. Because it is a hydrocarbon surfactant, it also has an affinity for carbons and causes the water (as foam solution) to penetrate deep into wood fuels.

Class A Foam has wetting and penetrating characteristics to reduce the combustibility of Class A fuels and makes water 10 times more effective. It can be used with fresh, sea, or brackish water and can be stored for up to 25 years in its original container. Pretreating an area with foam can greatly reduce the chance that the area will burn. Class A foam will adhere to vertical surfaces, increasing the protection it can give to a structure. After the fire threat is passed, clean off any foamed areas with water if desired.

Foam can be aspirated (entrained with air) through a fog or air aspirating nozzle, or a Compressed Air Foam System (CAFS) such as the one we use here at Consumer Fire Products, Inc. Different quality of finished foam blankets can be formed using these foam generation devices. Forming a low expansion, quick draining finished foam bubble blanket will yield additional fire suppression proficiency upon direct attack by enabling the foam solution to adhere to horizontal and vertical fuels. It can literally stick to the sides of a building, tree, or other vertical structure. The foam solution will remain on the fuel, penetrating or evaporating, until it is all gone. The net effect of using Class A foam in this fashion is that the available water supply is efficiently used to cling to and cool the fuel. This maximizes water’s ability to suppress the fire, rather than being wasted by running off of it. Penetration of Class A Foam into fuels will increase their moisture content and prevent them from burning. In addition, the Class A Foam will act as a barrier between any fire and fuel.

Click HERE to see how how foam compares to gels and fire retardant

Fire Command Center | WUI Maps | USFS Fire Management | Wildfire Discussions | CAL FIRE | Community Wildfire Plan | International Wildfire

©2010 Consumer Fire Products, Inc. All rights reserved.

©2010 Consumer Fire Products, Inc. All rights reserved.